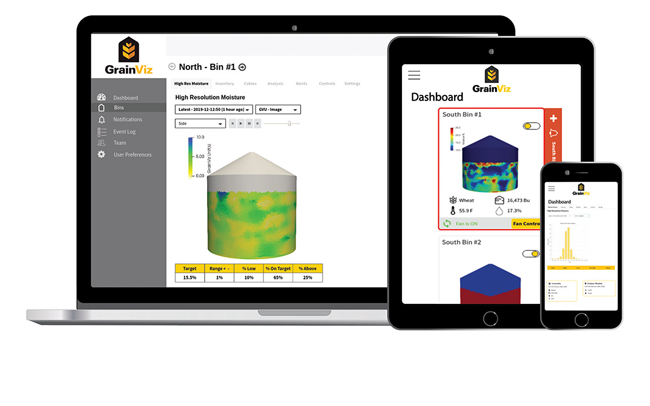

Grain handling specialist GSI is pleased to announce a revolutionary innovation in grain storage called GrainViz. Unlike systems that only monitor in-storage conditions in close proximity to cables, GrainViz uses technology similar to an MRI or CT scan to create a three-dimensional (3D) image map showing the moisture content of each individual tonne of grain and its location in the silo. The imagery generated allows grain growers and handlers to maximize weight, understand inventory, save energy and proactively address issues before they become a problem.

GrainViz is unlike any other grain storage system on the market, providing a complete and highly accurate picture of conditions in the whole silo or storage area.

Traditional cable monitoring systems will take readings of the air directly around each cable sensor and report a relative humidity and temperature value. This method is effective for areas close to cable sensors however, a large volume of the bin or silo remains unchecked.

The sensors in the GrainViz Imaging system measure the electromagnetic permittivity of the grain by sending out radio waves similar to that of a CB radio or FM radio. The GrainViz Imaging System can produce 3D images of the grain in the silo that pinpoint any areas of concern thanks to 24 sensors located inside the silo.

Each sensor sends and receives signals from the other sensors, and from these measurements, the 3D map of the properties of the grain stored inside the bin can be constructed.

The technology is based on imaging methods originally developed to detect breast cancer tumors.

Connected

With GrainViz, operators can see the moisture content of each tonne of grain and its location within the grain mass. The imagery and grain information can be viewed through a customer portal, which is accessible on any web-enabled device.

Being able to access the system and grain conditions in real time means instead of having to deal with problem spots in the stored grain after they are an issue means GrainViz users can proactively manage the quality and quantity of their stored grain.

GrainViz offers quick and accurate inventory reporting, eliminating the need for anyone to enter a bin to take physical measurements.

How is GrainViz different?

Current grain storage technology largely relies on cable systems to monitor the temperature of grain in close proximity to cables within the silo. Grain is a good insulator, so the majority of the stored grain can go unchecked.

Traditional temperature and moisture cables also read humidity rather than measuring moisture and traditional cable systems do not offer detailed inventory reporting like the GrainViz system does.

With 24 sensors mounted on the inside of the silo walls to construct the 3D image, users can monitor and manage each individual tonne of stored grain and GrainViz does not have to be used with cables, which can get in the way.

Not only does the 3D imagery provide the real-time and complete moisture content of every tonne of grain, it measures the exact weight of the crop in the silo.

The data generated by the Cloud-based system can integrate with existing precision agriculture platforms and a 24/7 portal access includes SMS updates (text alerts) and email notifications.

GrainViz can also be linked to local grain pricing information as well as weather station data to optimise energy costs associated with grain drying by turning fans on and off at the right times.

GSI estimates a 20-30 per cent energy savings/silo on average compared to traditional drying and monitoring systems.

GSI general manager Australia and New Zealand, James Lang, said if you are going to store grain on farm, you need to look after it to make it work for the best returns.

"There is an absolute payback for GrainViz for on-farm users. Buyers will pay a premium for good quality stored grain with reliable traceability and record keeping."

The GrainViz system can also be retrofitted to existing silos and can be purchased with AGCO Finance (to approved customer).

Remote management

GrainViz's customer portal makes it easy to remotely monitor and manage grain conditions and receive detailed inventory reporting via any web-enabled device. When a potential moisture issue is detected that could lead to grain spoilage, the system automatically sends notifications.

The system is also able to detect intrusions or activity by rodents and other pests such as insects.

GSI leading the way

GSI, operating under the AGCO banner, is building a reputation for providing complete grain handling solutions, from smaller farming systems to large-scale commercial installations. GSI's products and services, including GrainViz, cover everything from three-tonne capacity feed silos to complete bulk grain depots.

James said GSI fits into AGCO's vision of delivering smarter and more efficient technology to build a sustainable future in agriculture.

"AGCO's heritage is built on excellent machinery and GSI adds to the company's ability to deliver a full suite of products to handle post-harvest and general grain, seed and feed storage requirements," James said.

James said GSI is a proven global leader when it comes to grain storage and handling. "GSI is the world's number one manufacturer of silos by volume, covering everything from smaller cone-based storage under 10 tonnes capacity to massive 30,000 tonne silos.

"Our flat-bottom and cone-base silos can be built to meet Australian standards for sealing too, to help ensure grain is stored in the correct manner."

More information:

www.agcograinandprotein.com.au

GSIANZGrainSales@agcocorp.com

(03) 9313 0313 or 0447 469 767

ABOUT THIS COMPANY

AGCO GSI

Storing grain on your farm gives you more control of your operation. Maximise your profit potential with on-farm grain storage solutions from GSI.

HEAD OFFICE:

- 615 Somerville Rd, Sunshine West, VIC, 3020, Australia

- Website: www.agcograinandprotein.com.au

- Email: GSIANZGrainSales@agcocorp.com

- Phone: 393130313